Part Number: –

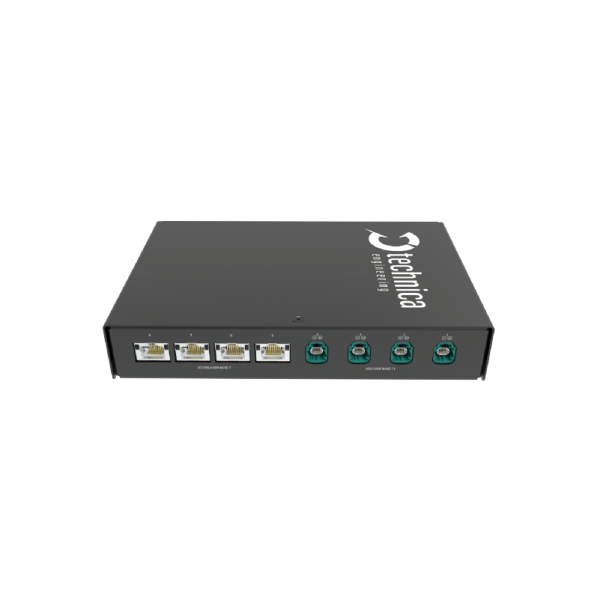

BTS Testsystem

Prototyp

Beschreibung des Produkts

Das BTS Testsystem (BTS) ermöglicht Automobilherstellern zentrale, hochkomplexe Steuergeräte in enger Zusammenarbeit mit dem Team von Technica Engineering zu entwickeln. Es bietet dem Benutzer einen breiten und tiefen Testumfang zur Umsetzung anspruchsvoller Testprojekte.

Die 12x konfigurierbaren Kanäle unseres BTS unterstützen CAN, LIN, FlexRay und verwenden das Ethernet-Protokoll (SOME/IP) für die Kommunikation. Somit kann das BTS Testsystem flexibel an die Anforderungen verschiedener Kunden angepasst werden. Es verfügt auch über einen steuerbaren Relais-Kanal zur Unterstützung der Steuerung.

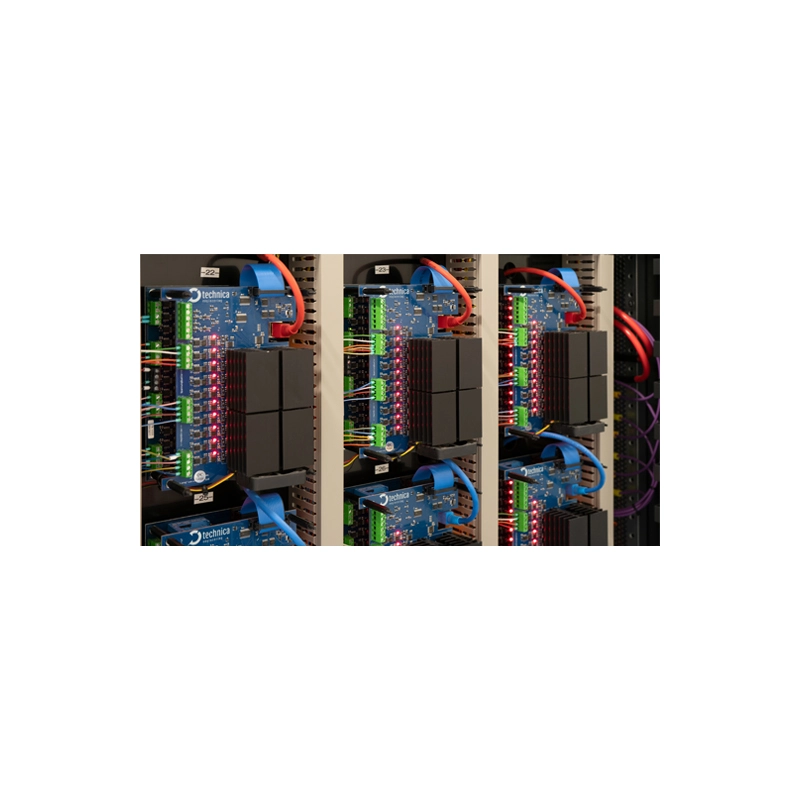

Als hochskalierbares Hardware-in-the-Loop-Testsystem (HiL) wurde das Body Electronic Test System (BTS) von Technica Engineering zur automatischen Validierung von Body, bzw. Domain Controller Steuergeräten entwickelt. Es wird kontinuierlich für neue Generationen von Automobilsystemen weiterentwickelt, um komplexe, zentrale Steuergeräte wie Domain Controller zu testen. Unsere Ingenieure können das BTS nach Ihren Anforderungen konfigurieren. Es verfügt über alle gängigen Hardwareschnittstellen und -systeme aus der Domain Controller Umgebung.

Das BTS zeichnet sich vor allem durch die Umsetzung von realen Lasten aus, aber auch durch die enthaltene, kontinuierliche Spannungs- und Strommessung an den analogen und digitalen Ein- und Ausgängen. Weiterhin machen die Shortcut-Funktionen zu den CAN-, FlexRay- und LIN-Schnittstellen über Ethernet (SOME/IP) das BTS zu einer einzigartigen Lösung auf dem Markt.

Der Kern unseres BTS ist eine generische Signalkarte, die alle notwendigen Ein- und Ausgänge bereitstellt. Über eine Softwareschnittstelle kann eine Vielzahl unterschiedlicher Anforderungen konfiguriert werden. Bis zu 32 Basiskarten können parallel betrieben werden, sodass bis zu 448 Ein-/Ausgänge bei maximaler Kapazität simuliert werden können.

Zusammengefasst haben Sie mit dem Body Electronic Test System (BTS) von Technica Engineering die Möglichkeit, Steuergeräte erfolgreich zu entwickeln und zu validieren, indem Sie eine ausgereifte Testbench mit einem tiefen, sowie breiten Spektrum an Testszenarien verwenden.

Wenn Sie Fragen haben oder weitere Informationen zu unseren BTS erhalten möchten, zögern Sie nicht uns unter sales@technica-engineering.de zu kontaktieren.

Technische Daten

FAKTEN

- Simulation von bis zu 448 Ein-/Ausgängen bei maximaler Kapazität

- 12 × konfigurierbare digitale und analoge (einschließlich PWM) Eingang/Ausgang-Kanäle mit integrierter Spannungs- und Strommessung

- 1 × steuerbarer Relaiskanal mit eingebauter Spannungs- und Strommessung

- 1 × steuerbarer Niedrigstromquellenkanal (Strom <35 mA) mit eingebauter Spannungs- und Strommessung

- 2 × High Speed/Low Speed CAN

- 2 × LIN-Busse

- 1 × FlexRay

- Anschluss von analogen und digitalen Signalen möglich

MERKMALE

- Vollständig per Software konfigurierbar: Jeder Kanal kann unabhängig als Eingang oder Ausgang konfiguriert werden

- Die Fehlerzustände „Leerlauf“, „Kurzschluss nach Masse“ oder nach „VBAT“ können für alle Kanäle simuliert werden

- Alle Kanäle verfügen über eine doppelte Selbstschutzfunktion, um Schäden an den BTS-Basisplatinen oder dem angeschlossenen Gerät zu vermeiden

- HW-Schutz zur Vermeidung von Stromstärken über 2A

- SW-Schutz mit konfigurierbarem Schwellenstrom pro Kanal

- Zeitsynchronisation zwischen den Boards über die CAN-Schnittstelle

- Für den Anschluss von Hardware-Erweiterungen zur Ausweitung der Funktionen der Basisplatine wird ein Anschluss mit Stromversorgungs- und Steuerungs- / Kommunikationsschnittstellen (3x SPI, I2C) bereitgestellt

- Zwei Möglichkeiten, um Änderungen in den Eingangs-/Ausgangs-Kanälen zu melden: Zyklisch oder bei Ereignis (On Event)

- Wiedergabe gespeicherter Muster in Fällen, in denen das Timing ein kritischer Faktor ist

Downloads

Wenn Sie die Bedienungsanleitung oder weitere Informationen zu unseren BTS erhalten möchten, wende Sie sich bitte an unser Technical Sales Team unter technicalsales@technica-engineering.de.

Passt gut dazu

Technica

Unsere Lösungen

Nichts verpassen

Tragen Sie sich in unsere Mailingliste ein, um mehr über unsere technischen Lösungen zu erfahren